Glastron GT-150 Page

Oh no, not another project.

Just bought this old 1978 Glastron GT-150 boat as a project. The

motor is a good working old Mercury 90 HP "tower of power" 2

stroke outboard, and the boat is the "James Bond boat" the same

model used for the boat chase scene in the movie Live and Let

Die with Roger Moore where the boat jumps over the sheriff.

Pictures will be added as the project is being

done.

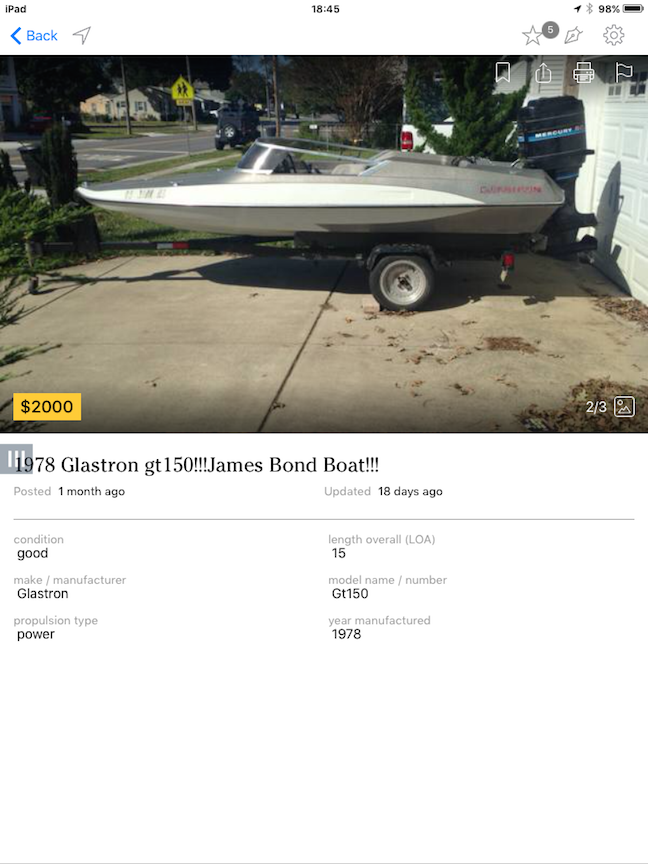

This is the advertisement that got it all started, though as it

was obvious the floor was rotten the price was negotiated down to

$1500, which seemed a fair deal as the Merc was in good running

condition.

Here are some other photos of the boat before tearing it down.

Overall appearance is not too bad, except for the crack down the

middle of the windshield.

Here is the Mercury 90 HP Tower of Power.

Unfortunate crack right down the middle of the windshield

Trailer was in pretty bad shape

Hull looks to be in pretty good shape

Seats and floor were rotten

None of the instruments were functional

Cool Glastron GT bow decoration

So, after a quick test drive the motor and steering seemed fine,

but my feet crunched right through the rotten plywood floor. I

removed the seats, and the seat bases were also rotten. After

removing the seats, I pulled up all the carpet and yanked out all

the rotten plywood floor. The 3 stringers were obviously rotten

too so they had to go.

Stern end after removing the plywood floor, revealing the rotten

stringers.

I used this multifunction vibrating tool to cut the fiberglass

tops off the stringers and pull out the rotten wood. A shop vacuum

was held nearby to suck up the fiberglass dust.

After cutting off the fiberglass wrapping on the stringers, a

groove was left to fit in the new stringer. I used 1 x 2 inch oak

about 102 inches long for each of the 2 small lateral stringers.

Even the battery holder base was rotten so it was ripped out and

used as a pattern to build a new one.

Here is the new battery tray, made of marine plywood.

After putting a layer of fiberglass on the battery tray it will be

more rot resistant. Just needs some edge trimming and will be

ready to install.

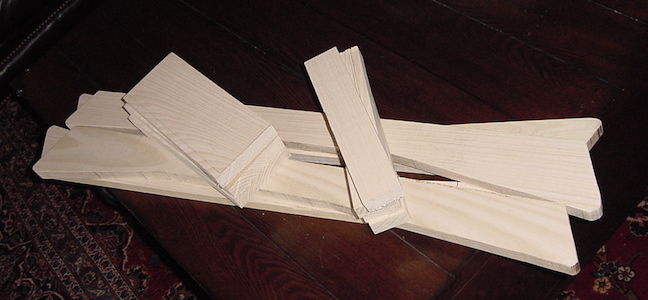

The bases of the seats were completely rotten. They were removed

and disassembled and then used as templates for the new ones.

The old parts were laid out on a new piece of hardwood, and traced

to cut the new pieces. Uh oh, project is invading the living room,

since it was raining and couldn't leave the wood outside.

Here are the new pieces of the bases cut out.

One of the seat bases assembled, sitting on the upside down seat

here. Will coat it with some polyester resin for waterproofing.

Both seat bases assembled now. Will probably have to do some

planing on the bottom to get them to fit the contour of the hull.

This is not the best photo, but shows the new center stringer

glassed in place down the center line of the boat. You can see a

bit of one of the lateral stringers, lighter colored wood on the

right. The tops of the 2 lateral and center stringer need to be at

the same level to hold the floor in place.

This shows the stern end of the center stringer. You can see some

fiberglass draped over the top and lapped on to the hull to

reinforce and hold it in place. I went a little crazy and used an

Ipe wood deck board for the center stringer. Ipe is a very dense

hardwood used for outdoor flooring and decking that is quite

moisture resistant and very strong. I just used white oak for the

lateral stringers and set the stringers into the channel remaining

after digging out the rotten wood of the old stringer. I shaped

the new stringers to fit and poured some resin into the channel

and overlaid the stringer with fiberglass to completely encase the

wood and help prevent future rot from water exposure.

Got the floor board cut out of a sheet of 1/2

inch marine plywood using a cardboard template. the bottom was

coated with fiberglass resin to help prevent rot. I put some

liquid nails on the tops of the stringers to hold the board down

initially until I glass it in. Next step will be to cover it with

fiberglass and resin, smoothing out the joints with the hull. I

had to cut out a triangle of the 2 boards that form the ski locker

at top center of the picture, and will replace those pieces and

fiberglass them in place. Once they are covered with the new

carpet, the splice will not be visible.

There were some strips of foam flotation under

the original floor that were glued to the hull. They were badly

waterlogged and would have provided no bouyancy, so i removed them

and replaced them with sealed plastic flotation chambers glued in

place to maintain the necessary flotation.

In order to slide the floorboard under the wood panels of the ski

locker, I had to cut off a little triangle of the bottom of those

2 panels to make room to tilt the big floorboard in and slide it

all the way to the front of the cockpit area. If you were doing a

really big restoration, you could take the whole top fiberglass

section off the boat but I did mine with the top section still

connected and replaced the stringers and floor up to the area of

the toe panels. In front of that, the wood seemed pretty solid.

After the floor was covered with fiberglass and sealed all around

the edges, (the bottom had been sealed before installation) I

replaced the triangles and glued them back in place. Next, I will

use some fiberglass strips to attach them to the floor and then

rebuild the little door frame.

Carpet Time

Working on the boat outside limits the time available to days when

the weather is nice enough to uncover it. We had six inches of

snow about 4 days ago and today it w as 65 degrees, so I got to

work and put in the carpet. I ordered the carpet form an online

place called Boat Carpet Direct and used DAP Weldwood All Weather

Outdoor Carpet adhesive to stick it down. I ended up using most of

a gallon can of the adhesive. The carpet was easy to cut with a

utility knife. It came in a roll that was 84 inches wide, just

right for the size I needed, and I got 15 feet, but could have

gotten by with 12 feet.

The backing of the carpet was flexible enough to smooth into the

contours of the floor. I used one big piece for the main part of

the floor, which was all I got done today. I will cut separate

pieces to cover the outside of the ski locker, and anywhere else

that needs coverage. Just having the carpet in place made a huge

difference in the appearance of the interior of the boat, so now

it is starting to give an idea of what the finished product will

look like.

Bad photo, but got the carpet done, including around the ski

locker. Replaced the throttle control and the seats.

Also put an automatic bilge pump in the small bilge well under the

fuel tank, and then replaced the fuel tank with the aluminum

brackets to hold it in place.

Just have a few electrical connections to make, including a 3

position switch for the bilge pump, On-Off-Auto.

Some more photos of boat now pretty much finished

Items left to finish:

Install new speedometer pitot pickup.

Remove the aftermarket trim tabs on the stern.

Do a few cosmetic gelcoat repairs on the hull.

Check out engine. Seemed to run fine on test

ride but may need new solenoids for the trim tilt control.