Double Doggie House and Chair Repair Projects

This project is a dog house for our 2 Labrador Retrievers to replace

the metal wire crates they have been using up till now. There are

similar items for sale in the internet, but they are priced well

over a thousand dollars, and I built this for about $250 in lumber

and parts. Below are the plans I drew up and parts and some photos

of the construction process.

Lumber used:

Top: 81.5" x 30.5" Maple clad 3/4 inch plywood cut from a full 4x8

foot sheet

Bottom: 80.25"x29.25" White melamine clad particle board cut from a

full 4x8 foot sheet

1"x4"x8' pine boards 7 pieces, these were cut to 4 pieces 80" long,

and 12 pieces 23" long

plus 1"x4"x6' pine boards 2 pieces, cut to 4 pieces of 27-1/2" long

for the sides, horizontal frame parts

1"x3"x6' pine boards, 2 pieces for the doors

Hinges 6 pierces for the doors

Gate latches 2 pieces for the doors

1/2 inch dowel rod, about 50 pieces for the bars, cut to 24 inches

for the long bars, or 18 inches for the doors

Plan Drawings:

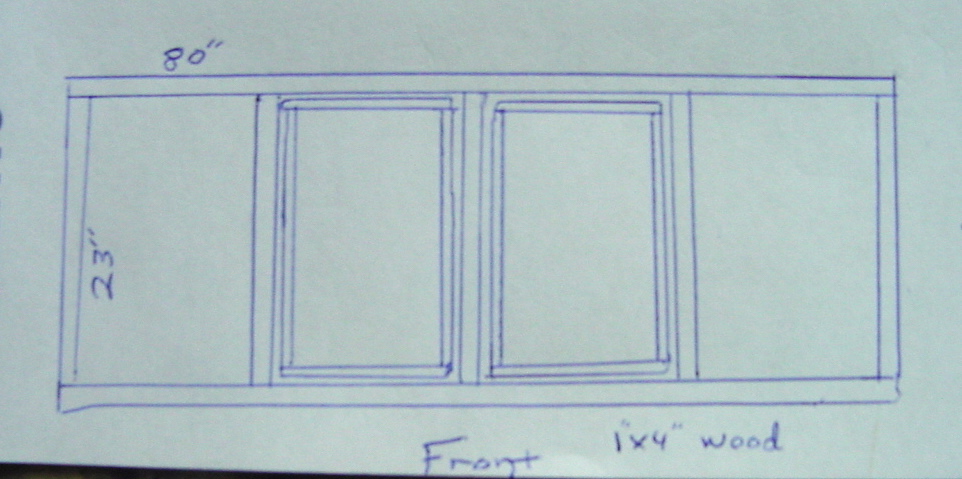

Front

The front is framed with 1x4s, which actually measure 3/4 by 3-1/2

inches. The lengths were cut to 80" for the top and bottom pieces

and 23" for the 5 upright pieces.

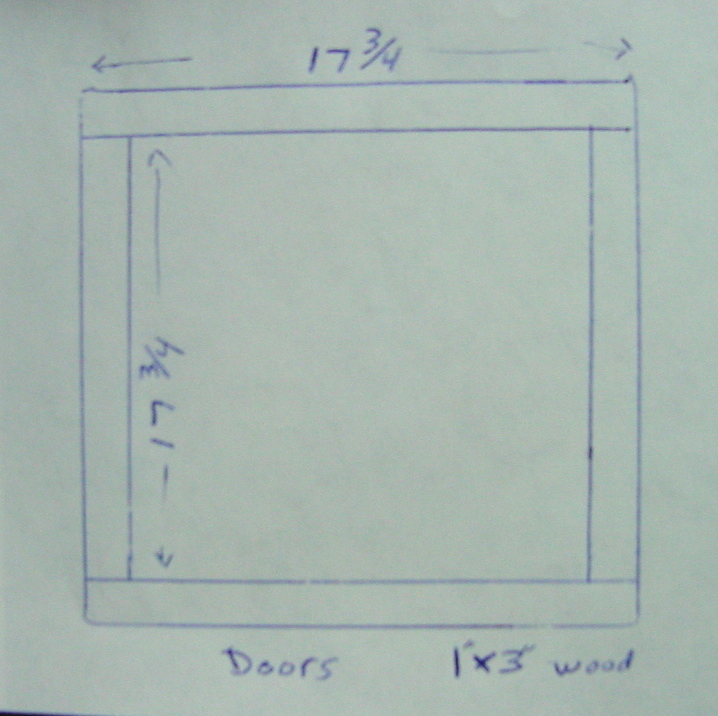

The doors were frames with 1x3s and all 8 pieces were cut to lengths

of 17-3/4 inches. When assembled, the doors measured 22-3/4 inches

high by 17-3/4 inches wide, giving a 1/8 inch gap above and below

the door. The middle upright frame piece was centered on the long

pieces, and the upright frame pieces for the hinges were placed to

give a 1/8 inch gap on both sides of the door frames.

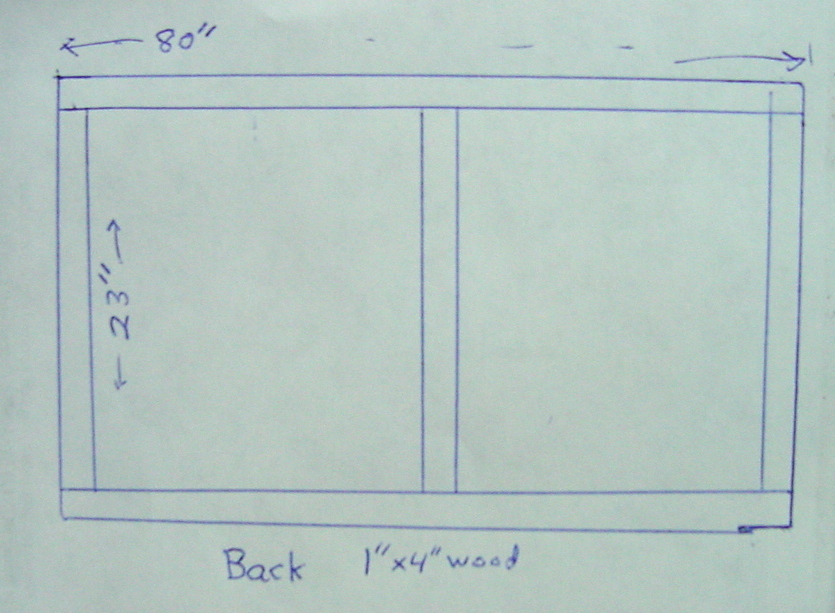

Back

The framing for the back is done with 1x4s cut to lengths as above,

with the middle piece centered side to side.

Sides

As the 1x3 boards are 2-1/2 inches wide, the actual height of

the doors adds up to 22-3/4 inches, giving a 1/8 inch gap top

and bottom as the upright frame pieces are 23 inches high.

Oops, forgot the diagram for the side panels. Sides were constructed

from 1x4s cut to 27-1/2 inches long for the horizontal pieces and 23

inches for the vertical pieces.

Construction:

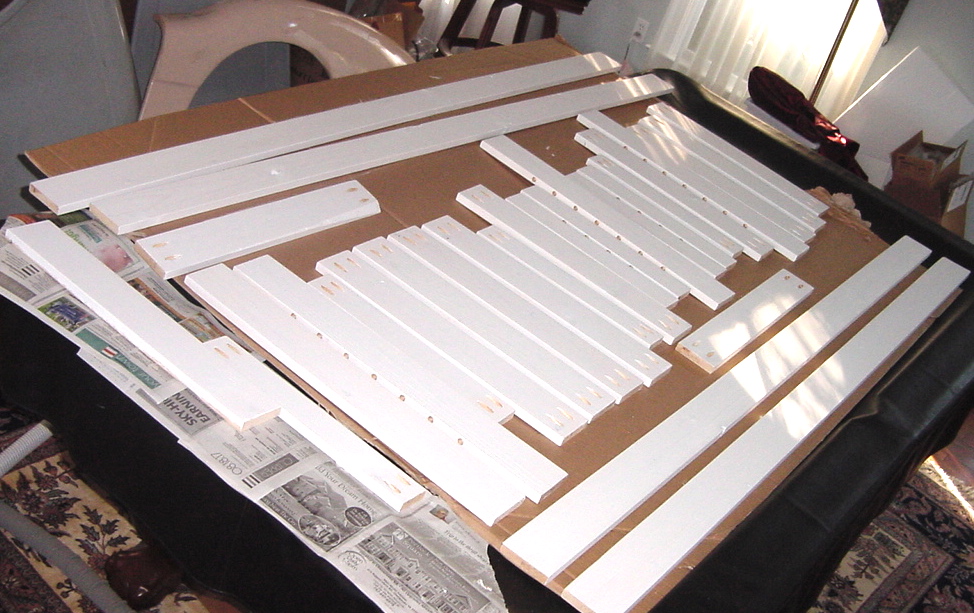

After drawing up the plans, I cut the 1x4s and 1x3s to the lengths

and laid them out.

This photo shows the front panel laid out with the doors in place

showing the 1/8 inch gap all around the doors.

A picture showing the side panel laid out on top of the front and

back panels.

I used a drill press with a 1/2 inch bit to drill holes about 1/2

inch deep into frame pieces to hold the dowel bars in place. They

are spaced about 2-1/2 inches apart, but you could use any spacing

appropriate for your needs. I saw some plans where they used either

1/2 inch or 3/8 inch steel rebar which would be stronger than the

hardwood dowel, but quite heavy and harder to cut and paint. If your

dog would chew through the wood dowel, then the rebar would be an

option.

Here are all the pieces laid out again, with the holes drilled for

the dowels, and the dowels cut to lengths of 24 inches and 18

inches.

I used this Kreg pocket screw jig to drill holes for the pocket

screws to hold the pieces together for assembly. It comes with

instructions on how to clamp the jig in place, and how deep to set

the stop collar on the drill bit, and what size screws to use. I

used 1-1/4 inch long number 8 construction screws.

Next, I painted all the pieces with one coat of Kilz primer, and a

couple coats of semi-gloss white paint before assembly.

The dowel bars were stained and the ends rounded over a bit to make

them slide into the holes easier, then the whole panel was laid out

and clamped in place and secured with the pocket screws and some

wood glue. It was a bit tedious getting all the dowels into the

holes at the same time.

Here is the front panel, all assembled, and the door hinges and

latches in place. Sides and back were similarly assembled.

Sorry I don't have photos of cutting the plywood

top, or the melamine bottom, but the top board was cut from a full

sheet of maple clad 3/4 inch plywood, and the bottom from 5/8 inch

melamine clad particle board. The top was sanded and the edges

rounded over, then stained with a colonial maple color, and

varnished.

The top board was placed face down on the floor,

so the frame could be assembled upside down onto the top, again

using pocket screws to attach the top to the frame.

The bottom board was then screwed onto the frame and some little

feet were attached.

Then the whole thing was flipped over to be right side up. I used

some little dowel plugs to fill in the holes on the front frame

where the screws were countersunk into the wood.

Since we have 2 dogs, the interior was divided into 2 sections using

some dowels run through some holes in the back panel.

The finished dog house, just need to add the standard 40x27 inch

standard size dog beds and a couple of dogs.

Chair Reupholstering project

Our 35 year old dining room chairs were starting to look

pretty bad, but the frames were in good shape, just need new

upholstery material.

Turns out, we had some nice blue material that was meant to be made

in to curtains but that never happened.

First thing was to unscrew the screws holding the seat to the frame.

Then the seats just lifted off the frames.

If one were using the original seat base frame again, then all the

little staples have to be removed, and the old upholstery material

and padding removed from the wood.

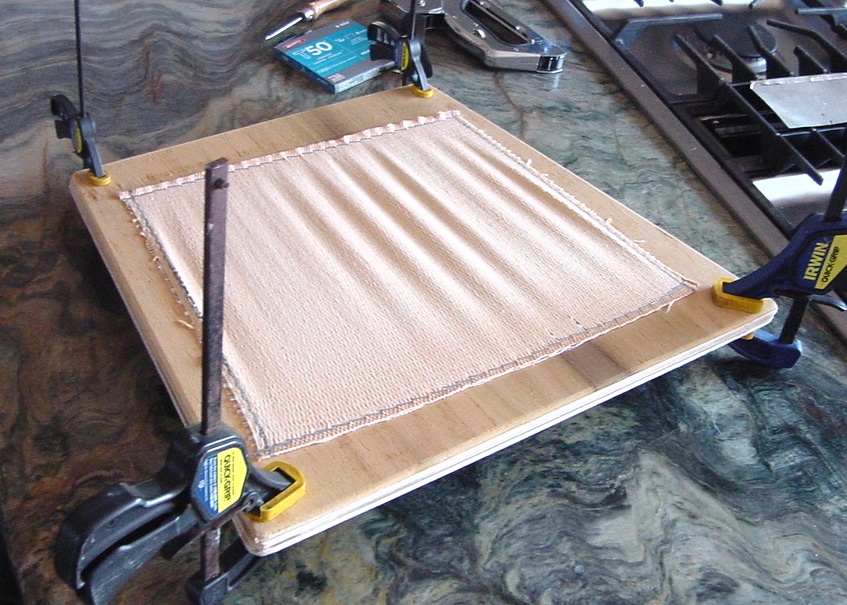

My chairs had these open frames, which gave you the feeling of

sitting in a hole, so I added a piece of 1/8 inch luan underlay

plywood to fill in the hole.

I glued the extra wood onto the old seat base to fill in the hole

and give a firmer seat.

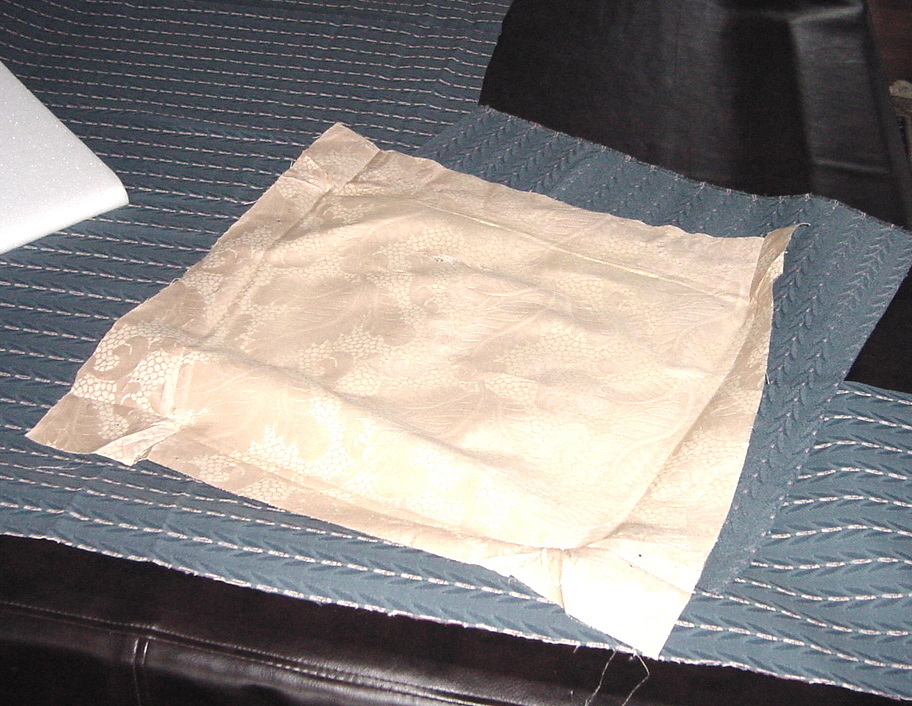

The old material was used as a template, and the new material was

cut to size.

New cushion foam was then cut to size for each chair.

The hard part was stapling the material to the wood base with the

material straight on the frame, and just the right amount of

tension, to avoid any puckers.

Beginner's luck prevailed, and my first attempt at furniture

upholstery passed the spousal inspection and not only look better

but are far more comfortable than the old seats were.