Assembling Blue 1960 Austin Healey 3000 BT7

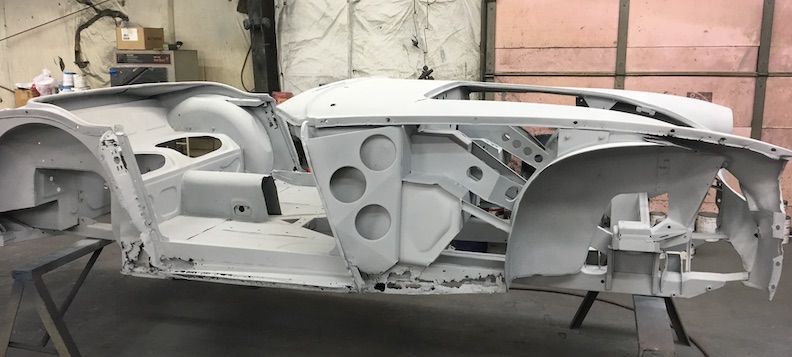

Finally got the body back from the paint shop

after about 2 years, but the paint job is excellent. Now to

start the assembly process. This is a chronological record of

the reassembly. Over the 2 years that the body was in the shop

getting the finish body work and paint, I rebuilt the main

components and assembled various subunits, so the seats are all

upholstered, and the dashboard is done with all the instruments

installed, so mainly the job is to put it all together. After

restoring the red Austin Healey, my wife thought I had gone

totally crazy to buy another basket case junker, but this one

appeared to have "good bones" and I succumbed to the temptation

and did it again. It sat in the garage for a couple of years,

then another year or so to disassemble everything. The frame was

good, the rocker panels and rear door pillars were rusted out,

as were some of the floor panels and lower parts of the fenders,

and footwell panels. It had been in a barn for many years and

all the wiring was shot, and the upholstery was rotted. The

engine, gearbox and overdrive needed complete rebuilds, as did

every other component. As you can see it was stripped down to

the frame, and one shop did a sandblasting job, and I managed to

replace some of the body components such as the footwell panels,

rocker panels, door pillars, and patched up some wheel well

rust. The body shop did the rest where it needed to look good

and welded on the fender repair panels from Moss Motors, and

straightened out some dents in the aluminum shroud, which they

actually removed from the frame for better access to get

everything primed and painted.

Here are a few "Before" pictures of the car as I got it.

Original color was Old English White, but someone had added the

2 tone maroon paint.

The upholstery was completely rotted as were rocker panels and

lower fender sections.

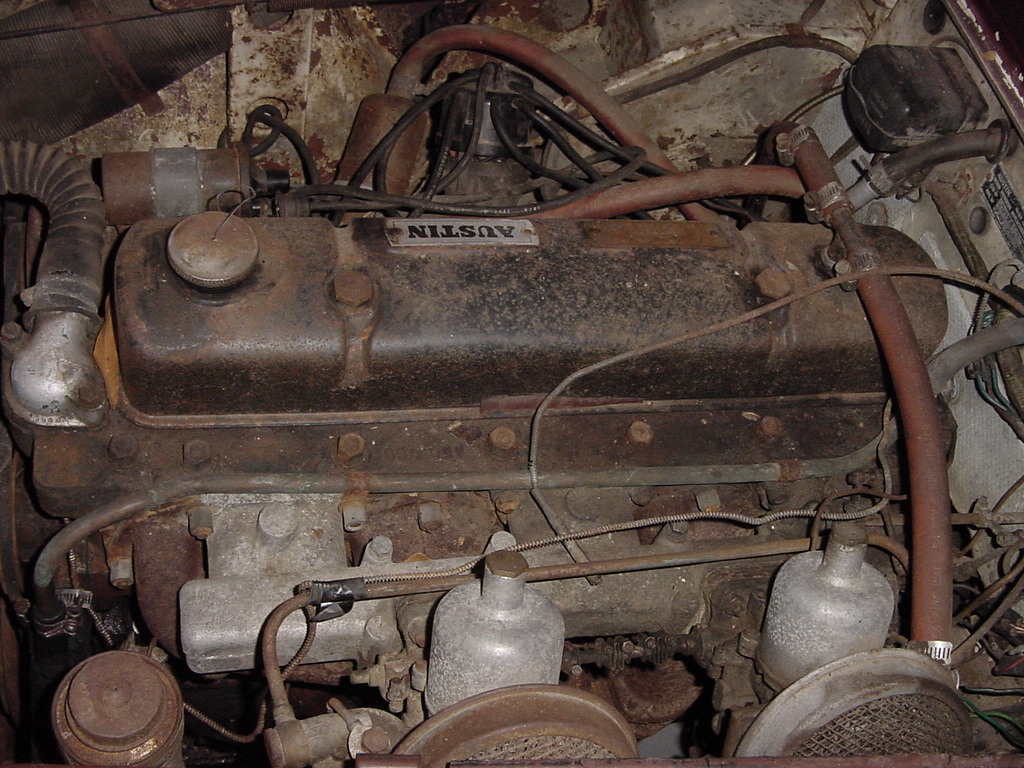

The engine compartment was quite grungy but the engine wasn't

seized. Still did a full rebuild anyway. Above photo was taken

after removing a lot of mouse nest mess and a few dead

mice.

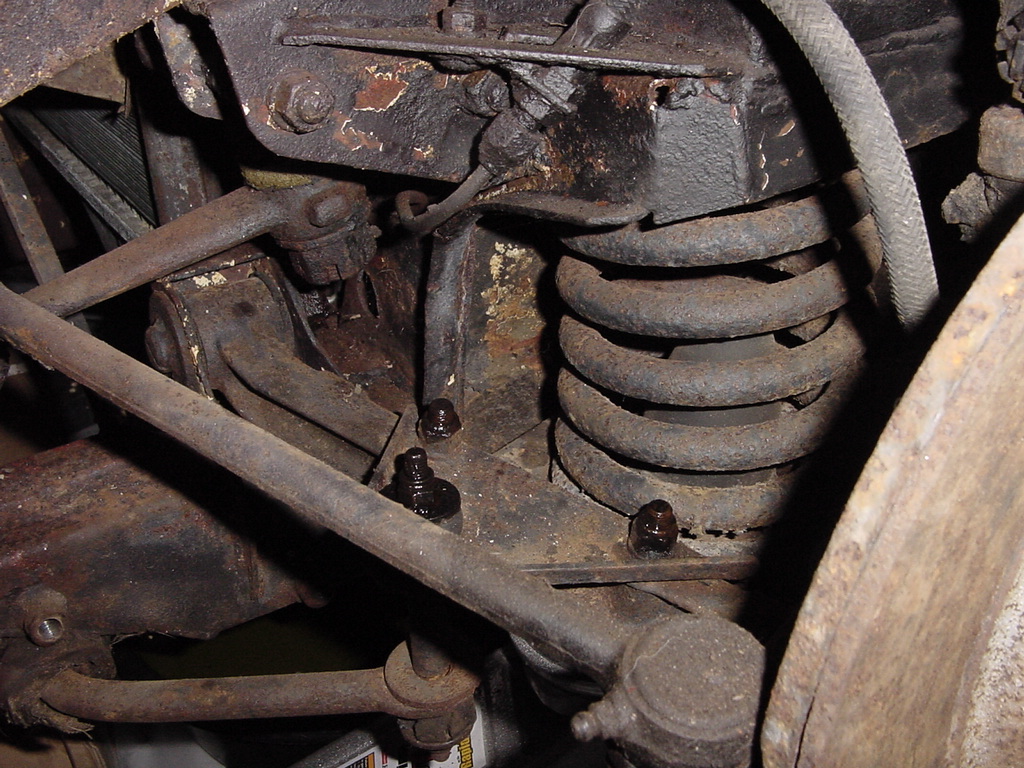

Everything underneath was black with greasy grunge. A lot of

stuck nuts and bolts to undo. Tear down and parts cleaning and

rehab took a year or so, and below is only the reassembly

process.

Some photos of the chassis at the sandblasting shop, they

sprayed on primer as well.

Obvious bad spots were the rocker panels, door pillars, inner

and outer sills, all of which were cut out and new ones welded

in.

Floor panels and main frame were in surpisingly good shape,

unlike the door pillars and sills.

Back end needed some new sheet metal under the fuel tank.

Front end needed a fair amount of work on the shroud.

Here are a few photos from the shop where they did the paint job

and finish body work.

Week 1

Doors:

I got the doors back before the main body, so

I started putting those back together. The hinges were already

attached and painted body color. There is a strip of upholstery

vinyl glued (contact cement) on the inside of the door near the

upper edge to fill in the gap between the aluminum trim molding

and the inner door panel.

Door latch assembly. Next I installed the

door latch assembly, the long connecting rod and the inside

control unit, called the remote control in the Moss catalog.

Those parts had been cleaned up and lubricated so they work

smoothly. The outside door handles were installed along with the

gasket and the little rubber buffer. checking that they were

installed on the correct side so the lever engages the latch

mechanism when you pull the door handle.

Check straps: Attached the check straps using

the chromed screws, plain and lock washers, careful to get them

right side up and on the correct side. I taped them down with

some masking tape so they don't bang around and chip the paint.

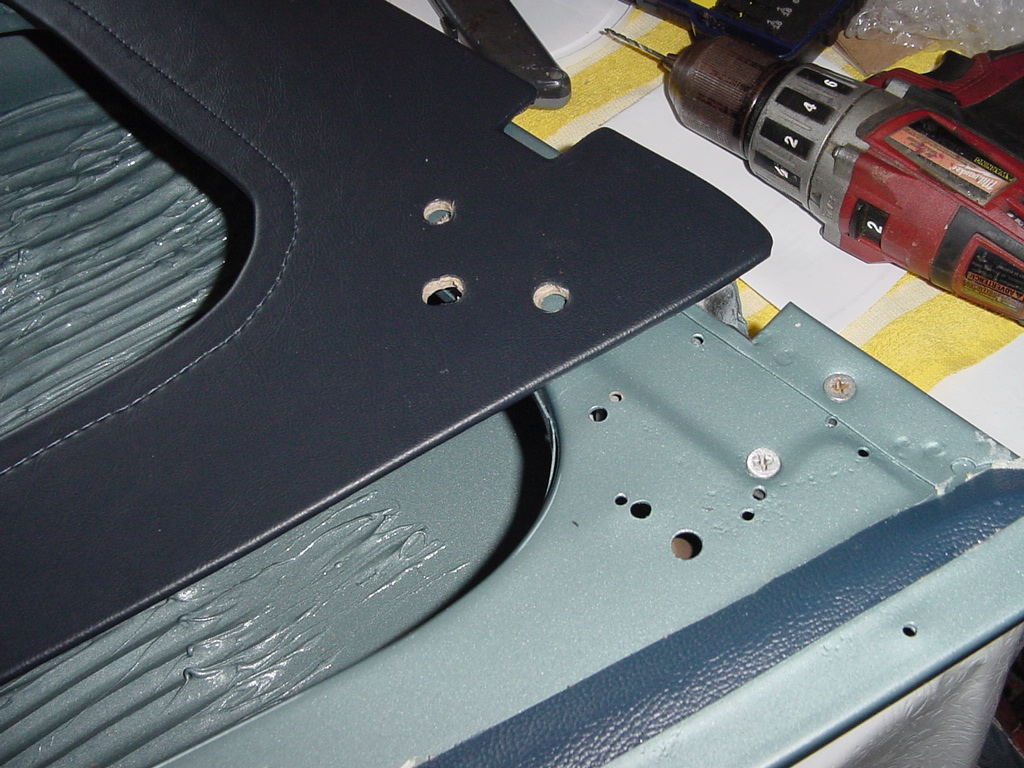

Door Panels: The three panels inside the door

cavity go in next, the little bottom one goes in first and the

other 2 are held in by 3 trim screws. The ones I got had some

lines impressed into them but I had to pretty much break them

along the lines to get them to bend to 90 degrees. I marked the

position of the wood strip on the sides of the door frame to use

for positioning the screws, and drilled a tiny pilot hole 3/32"

and screwed them in place. The third little trim went in first

and just lays in the bottom once it is bent along its length.

Once all that is on, I put on the main door panel. I had to

drill pilot holes through the panel and the metal, since you

can't really locate the original holes in the metal through the

panel. I used the old panel as a ballpark template for where to

put the screws.

Door Hardware: The inside door handles were

kind of a pain to install, as it was hard to push down the inner

ring of the escutcheon in order to place the pin through the

shaft. It was easier after trimming the panel backing around

where you push that piece down, just be careful to avoid cutting

outside of the diameter of the larger escutcheon ring. The side

curtain attachment plate goes on with 3 screws, some used sheet

metal type screws like mine, and some used machine screws with

nuts and washers. I prepunched some holes through the panel

where these screws go through. The lower screw tends to hit the

door latch mechanism, so I ground that one short enough to avoid

hitting it but long enough to grip the panel metal.

Front Fenders: The only thing I did at this stage is to install

the chrome trim flash using the 3 nuts with plain and lock

washers since you can't get to those once the fender is

installed. Make sure they are installed pointing the right way,

see photo.

Body: Since paint gummed up most of the threaded bolt holes on

the frame and body, I spent a couple of hours running a thread

chaser through all the holes so the bolts will engage properly

without getting jammed up. There are a lot of them and it took

most of an afternoon.

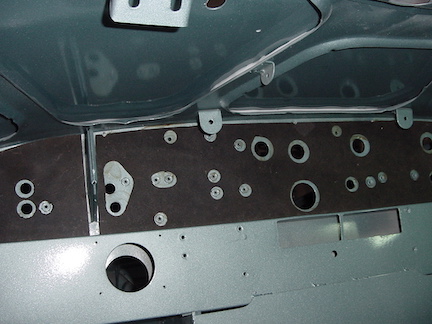

Firewall tar paper: Glued on the firewall tar paper using

contact cement. Lots of wires and stuff go through the holes so

you can't put it on later.

Heat Shields: I got a new set of heat shields and attached them

with the screws and big washers supplied in the kit.

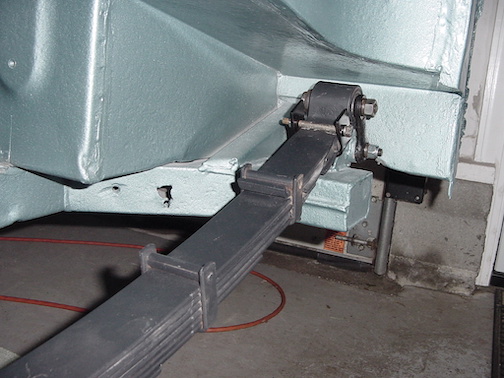

Rear leaf springs: No particular reason for putting the rear

leaf springs on at this point, but it didn't seem like they

would get in the way of anything else and they were taking up

space in the house so on they went. The springs had been

sandblasted primed and painted and I had new bushings and new

rear link pins. I used Nylock nuts on the rear link pins in

addition to the lock washers. The grease nipples on the rear

supports had been painted over by the body shop so I cleaned

those up and shot some grease through to make sure they would

pass the grease through. I also bolted on the buffers with the

rubber pads on to the upper surface of the main frame members. I

also greased up the front bushings since there didn't appear to

be any grease fittings on them for later use. It was a tight fit

putting the bushings into the loops at the end of the springs,

and I used a big socket and a hammer to pound them in place so

as to avoid hitting the bushing itself.

Gave up on the timed weekly updated, so will just update as I go

along.

Boot Area: Armacord etc. The black boot (trunk) liner comes

as rough cut pieces that you need to trim to fit. I used some

giant magnets to hold the pieces in position them marked and

trimmed them with a sharp utility knife. They are best to install

in a certain order to have the bound edges overlap on top of the

cut edges. I will show the order I used:

TIP; Put some masking tape over the screw holes so you don't

gum them up with glue, and don't glue down the edges where you

need to install the fender screws or other items. Glue those areas

later. After gluing a piece down let it dry then push a pin

through the places where you need to cut a little hole for screw

holes for the wood tire blocks and battery block. Use a utility

knife to cut holes where the battery and tire block screws pass

through.

1. First the piece over the curved part of the left wheel

well, cut and glue in using carpet glue.

2. Second is the flat piece in front of the battery. Glue in

place.

3. Third is big piece on the front wall. Hard to trim and needs

holes cut for the gas tank strap anchors. Glue in place so the

bound edge on the left side covers any gap over the the left

fender well piece. There are also 6 rivets holding this piece,

locate the holes by pushing a pin through and using that spot to

push the rivet in place. Don't glue the corner where the wiring

harness comes through the wall.

4,5. Next are the 2 side pieces of the flat fender walls, trim and

glue in place so the bound edges cover any gaps, tape over screw

holes first, and don't glue down the spots where the fender screws

go through until after those screws are in place.

6. The next piece is the rear piece behind the gas tank, trim and

just lay in place.

7,8 There are 2 smaller side pieces to trim and just lay in place.

9. Last is the big piece that covers the gas tank, but haven't

installed it yet.

Gas tank Gasket: The foam gas tank gasket needs to be glued in to

keep it in place. I used some clamps to hold it while the glue

dried.

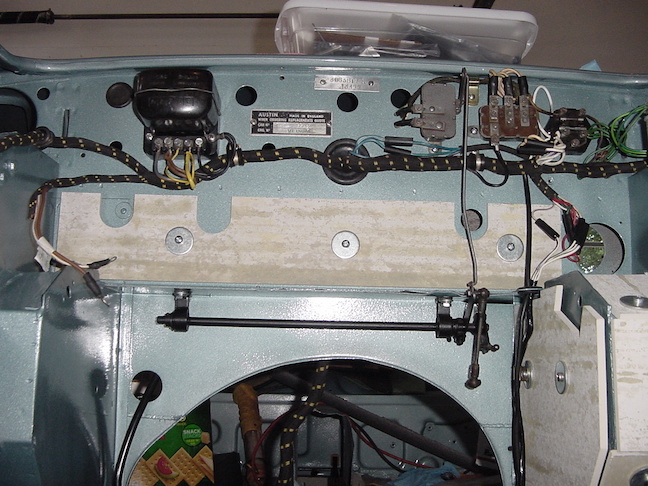

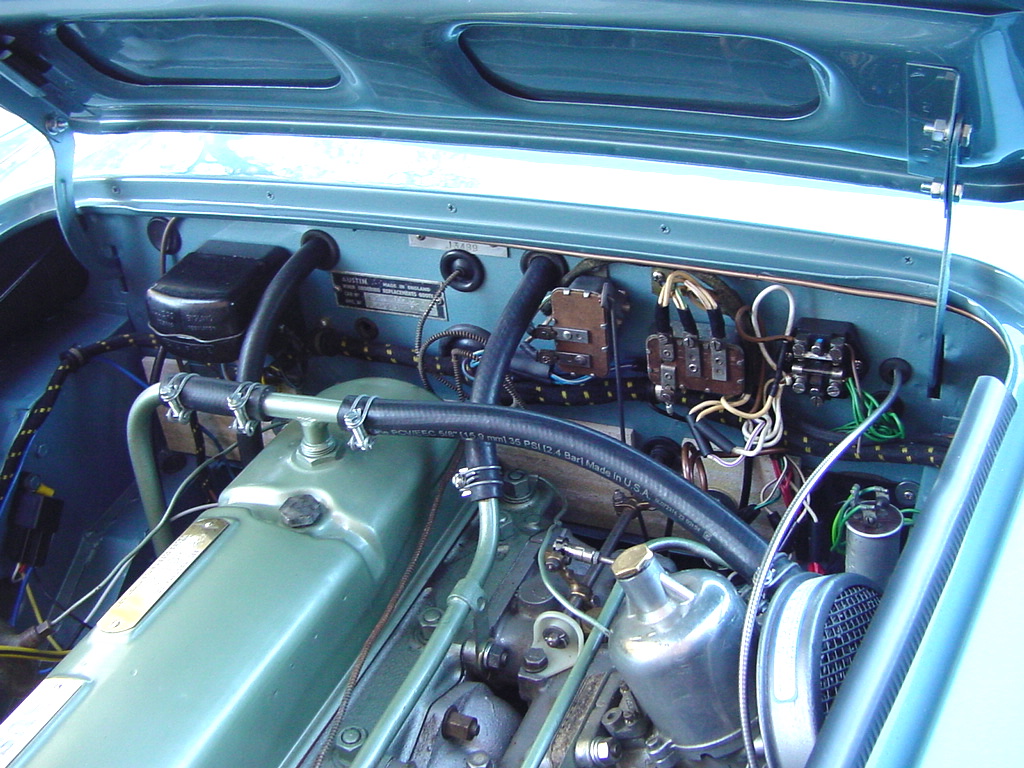

Engine Compartment Components: Lots of electrical components here

to screw onto the firewall. I did my best to test the components

that I reused, and installed them. Also put on the accelerator

shaft and the rear bolts on that were hard to get to, used a small

box end wrench and connected the little rod to the throttle

position switch.

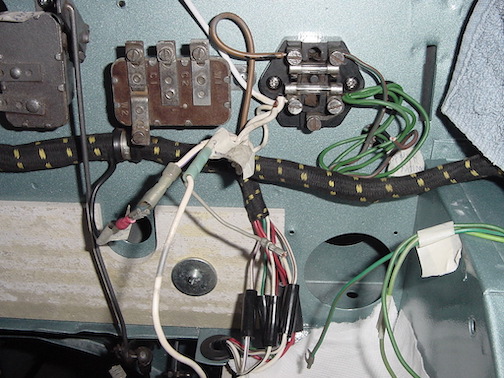

Wiring Harness: Before installing the harness, I tried to mark the

wires with tape to show what they connected to, referring to the

wiring diagram.My harness was not exactly the right one and had

some push on terminals where I needed bullet type, so I had to cut

off the push terminals and solder on the bullets where needed. I

was able to reuse the overdrive harness.

Note: I think I should have installed the oil pressure gauge pipe

before all the wiring as it was difficult to get in later.

Firewall all wired up and accelerator shaft in place.

Horns: The original horn circuit has hot wires going to the horns

and back up the steering column and the horn button then completes

the circuit to ground, so a lot of current is flowing through the

horn button. In spite of trying to keep the car as original as

possible I made a few concessions to improve functionality and

installed a relay so the only current that flows through the horn

button is what is needed to trigger the relay, and the relay then

completes the circuit and the horn sound is much clearer. I used

the same kind of relays for the headlights, so the only current

through the light switch is the trigger for the relay.

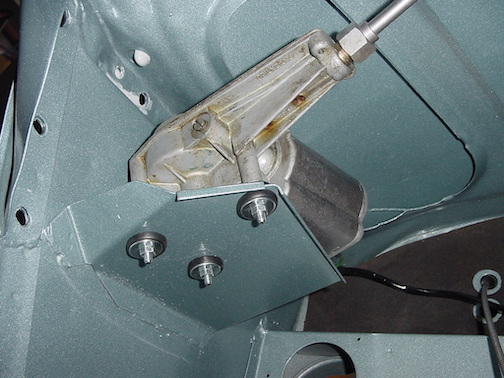

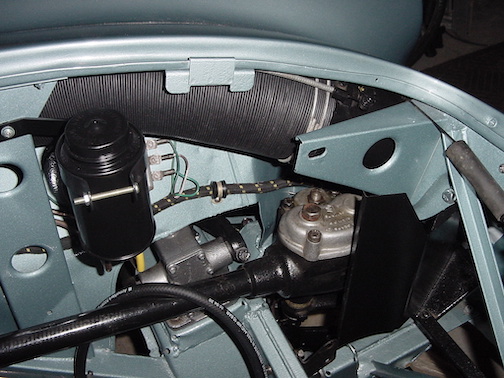

Wiper Motor: Installed the wiper motor on its bracket. The new

bushing kit was impossible to push the grommets through the holes,

so I ended up cutting them and putting the 2 halves in one on each

side so you can't see they were cut. I connected the wires before

mounting the motor as they were hard to reach after mounting.

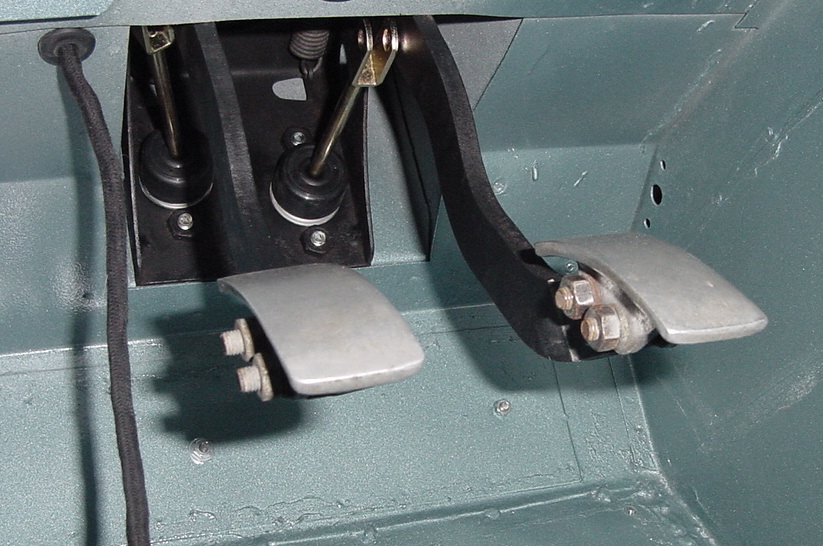

Brake Pedal Box: I installed the brake/clutch pedal box with the

6 bolts without the master cylinders just to get it positioned and

firmly in place. Then I removed the 2 bolts that would hold the

brake master cylinder and inserted that master cylinder and

screwed down those bolts. Then I removed the bolts for the clutch

master cylinder and inserted that one and screwed it down. This

was much easier than trying to hold the box in place with just the

2 upper bolts holding it. Attached the plungers to the pedal arms

with the clevis pins. That part was done lying on my back looking

up at the plungers in order to see what I was doing when inserting

the clevis pins and cotter pins.

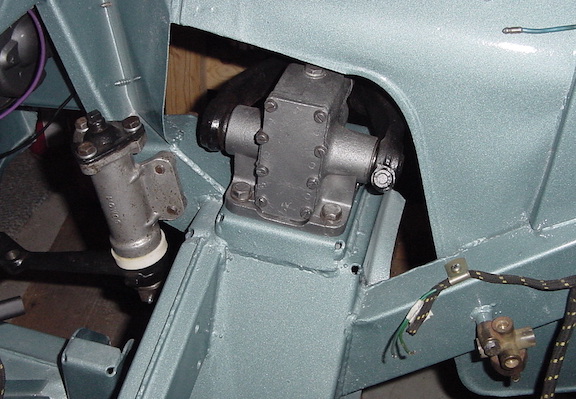

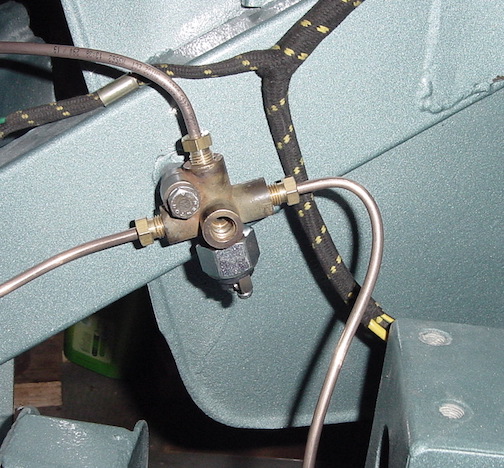

Steering Idler, Front Shocks, Brake 5 way block: I

installed the little front shock absorber buffers and then the

front shock absorbers, just bolt them onto the shock platform.

Then attached the steering idler using the 3 big bolts and the

alloy spacer. Installed a new brake switch on the 5 way block and

attached that onto its post.

Splash Guards: These attach with 4 sheet metal screws, though I

had to upsize the screws to get them to hold. There is a bracket

to attach to the front lower edge, but the other end of it will

attach later when the front grille is installed. Don't put these

on until after you install the horns or you can't get to them very

easily.

Battery Switch: This was attached to its bracket in the boot. I

used some White-Out correction fluid to re-ink the writing on it.

Rear Axle Differential: Had a friend here today to help with the

heavy rear end installation. TIP: Might even need 3 people to do

this or 2 big strong guys. Install the bump stop boxes AFTER the

rear end, and maybe even the fuel pump so those don't get in the

way. Basically we just wiggled it in place and tipped the front of

the differential up about 45 degrees to get it started, but

smashed a finger when it set down on the frame member. I used a

heavy wire after it was in place to keep the front from tipping

down due to the weight and had it resting on the frame buffers.

Will need to put the jack under the leaf springs to get them to

mate up with the axle. Put the fiber pad in place and then the big

U bolts and plate underneath. Had to unbolt the rear shocks from

the frame to get the shock links inserted through the spaces on

the axle, but forgot to put those "distance pieces" in place so

had to do that job again with those in place.

Haven't bolted it in place yet, or attached any of the parts yet,

waiting to get the fiber pads from Moss Motors.

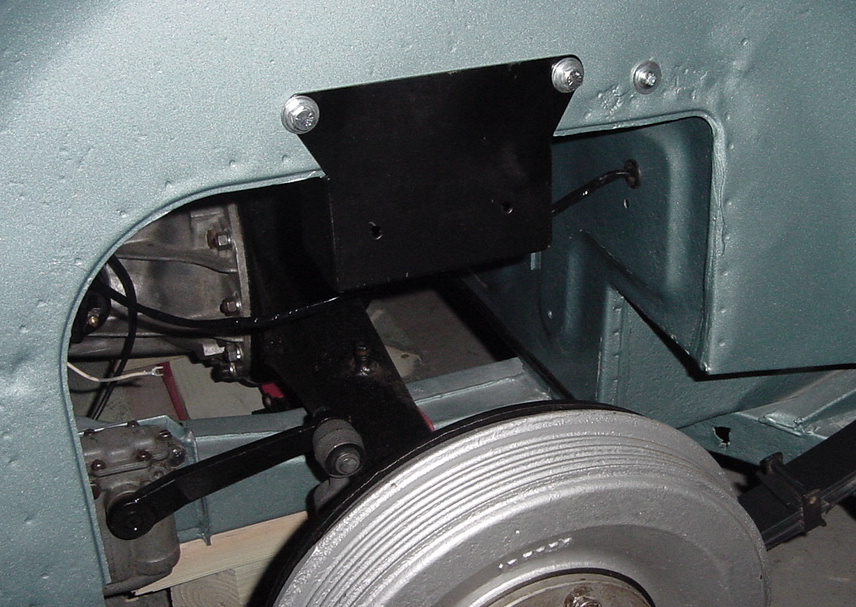

Rear Seat Bracket: This bolts on through the rear fender wall to

hold the rear seat and the rear quarter panel in place. I had to

trim off the bolts from the bump stop box to get clearance for the

quarter panel to tuck under the bracket.

Bump Stop Box: Put this on after installing the differential.

Uses four 1/4 inch bolts. The new boxes didn't fit properly as

they were and I had to use a grinder to cut the channel for the

body seam, and even then had to file the screw holes to line up

with the holes in the fender well wall.

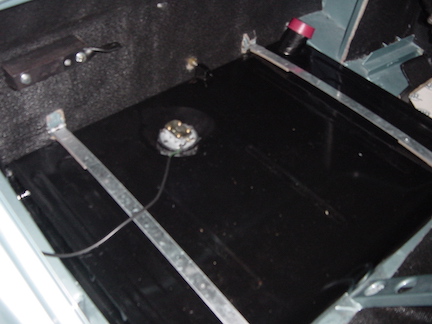

Gas Tank: The foam support for the gas tank was a bit too thick

and the outlet for the fuel couldn't clear the hole in the wall,

so I had to slice off about half an inch of height to get the tank

outlet to go through the hole. I installed the 2 metal straps

using the clevis pins and the nits and big D shaped washers in the

back where they go through the floor of the boot. TIP: Screw on

the section metal fuel line before strapping down the tank, and

remember the rubber grommet where the fuel line goes through. The

wire for the fuel sender is screwed onto the post. Then you can

cover it all up with the Armacord trunk liner.

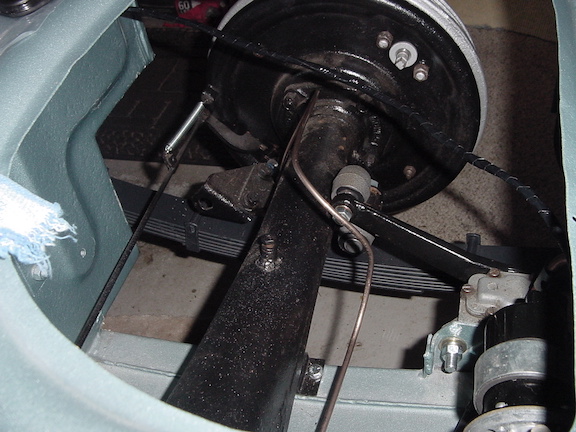

Rear Axle Stuff: The hydraulic brake lines and handbrake need to

be connected to their places The photo shows the left side with

the new brake pipe bent to fit. It goes up over the top of the

differential and there is one clip at the top of the diff that is

held by the top screw in the differential housing. This clip has a

larger mounting hole that fits the housing screw. The left rear

brake pipe attaches to the 3 way union which in mounted on a

little extension bracket on the right side of the axle housing.

The flexible hose attaches to the front hole of the 3 way union,

take care to put in the copper washer here as the washer

compression forms the seal. The front end of the flexible hose

goes through the hole in the bracket on the heelboard, and the

main front to rear pipe connects to that.

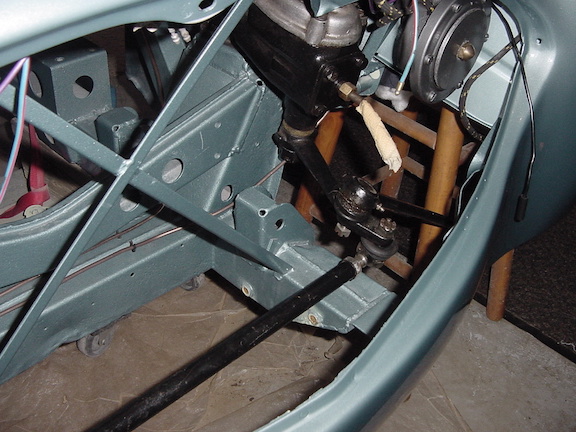

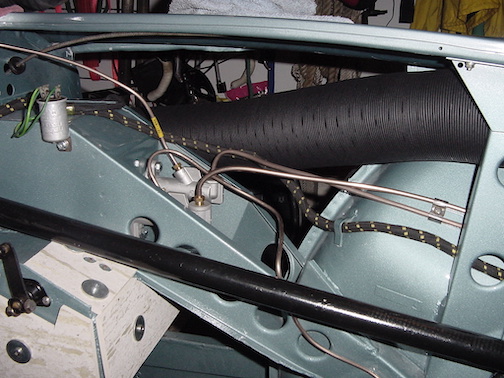

Steering Column, box and Support: This will be installed using

the little bracket that holds the 2 bolts from turning that goes

inside the air duct so the bolts go down through the holes. TIP:

Put the little 2 bolt bracket in place first, then put the

steering box and column in place, then wiggle the column support

bracket over the column and bolt everything in place. Make sure to

put the alloy spacer in place where the bolts attach the steering

box, and make sure you have put the blanking place, grommet and

felt washer onto the column before inserting it in place. I had to

adjust the position of the firewall heat shield a bit to allow the

blanking place to go into its place.

I stuffed some paper towel into the hole in the steering column to

keep me from banging my head on it when working in the

cockpit.

Brake Pipes: I started to install the brake pipes, even though I

haven't attached the front suspension yet. I still had the old

pipes and used them as templates for bending the new pipes into

shape to fit, since they were purchased in coiled form. I started

with the ones on the rear axle, then the flexible hose from rear

axle to frame, then the long front to rear pipe which used several

of the clips to hold in place, then the front left and right

pipes. Already out a new brake light switch on the 5 way

union. Be careful when screwing the pipes into the unions as they

are easy to crossthread.

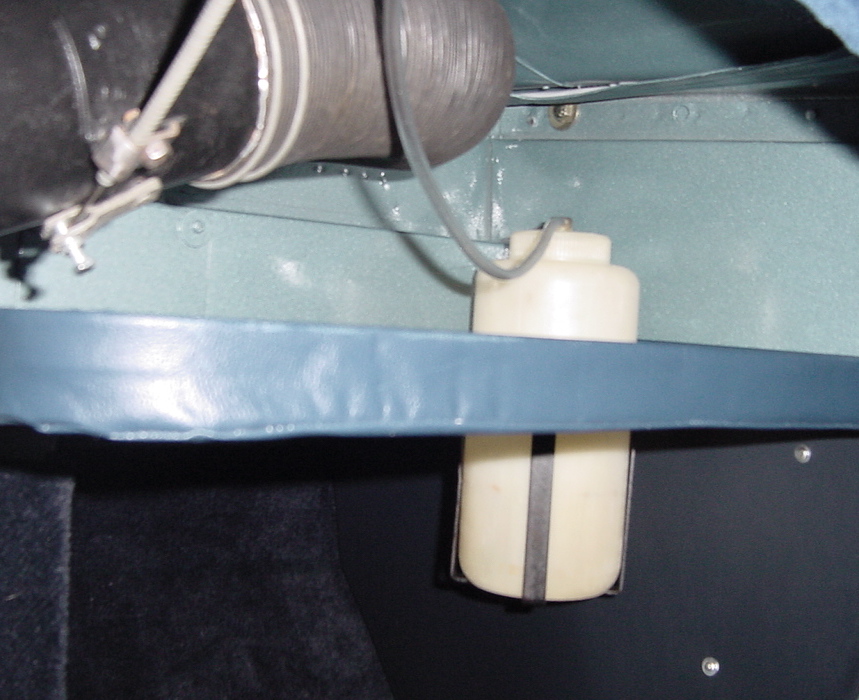

Brake Fluid Tank: The tank for the brake and clutch fluid is

mounted on a bracket as shown, and the pipes running to the master

cylinders. It is important to get the ends of the pipe lined up

for a good fit to avoid leaks, so some extra time getting them

bent just right will pay off.

Steering rods: Now that the steering box and idler are in place,

I installed the cross rod. Remember is you need to adjust the

length that one side is left hand thread.

Handbrake: Didn't really need to put this in place just yet, but

wanted to get the brakes done and can work around it when

installing the cockpit stuff.

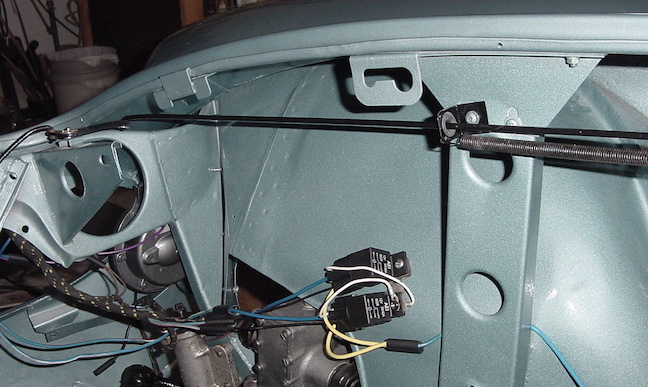

Bonnet Release Rod: The bonnet or hood release rod is inserted

from inside the cockpit side and slide on the firewall grommet and

the spring adjuster onto the rod as it goes through the bracket on

the side. The end is connected to the lever with a washer and

cotter pin. I put some Teflon lubricant on it where it goes

through the grommets so that it slides more easily. You can also

see in the second photo the 2 relays that control the headlights.

Boot Lid: Working on the boot, or trunk, lid. Installed the prop

rod with a new grommet and new rubber clip, and attached the

emblems with the spire nuts. The rubber gasket has to be glued on,

am trying silicone glue and will see how that works. I don't know

what they used originally but it is a pain to have to clamp the

gasket in place until the glue dries, and then move along a

section at a time to get it all glued down.

Convertible top snaps: These are called Tenax fasteners for

attaching the soft top. I used the originals and cleaned them up

and got some nickel plating solution to improve the color as they

looked more brass than silver. There are little leather washers on

the outside so I got new ones for those and used most of the

original metal washers and nuts underneath.

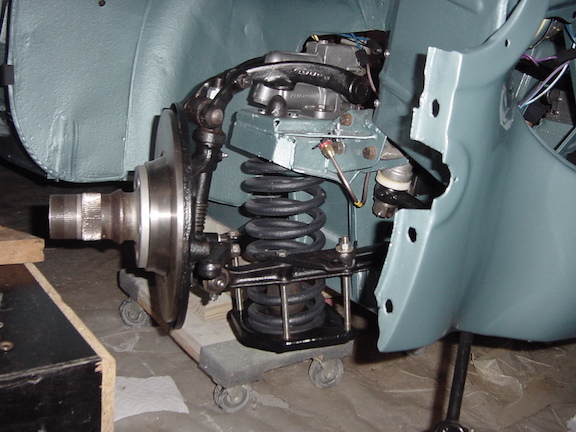

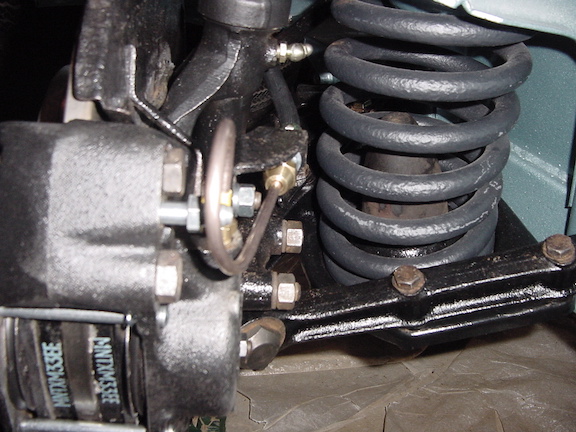

Front Suspension: I bought new kingpins and had a machine shop

replace and ream the bushings in the swivel axles and the kit came

with various new washers and lower fulcrum link pins and bushings.

The new king pins used big nylock nuts on top and were not drilled

for the cotter pins. I squeezed the various rubber bushings onto

the lower link arms and upper trunion, but everything was still a

pretty tight fit, finally wiggled everything into place. Had to

spread out the 2 shock arms a bit to squeeze the upper trunion

bushings into them but everything finally fit. Put in the 2 inch

block under the shock arm and tightened up the bolts and cotter

pins where applicable. One of the new inner lower link fulcrum

pins also came with a nylock nut rather than a cotter pin. I will

be using the long bolt method to install the front coil springs.

Don't forget to put the roll bar plates in place on top of the

front lower link arm before putting the bolts through for the

spring plate. Tighten up the long bolts then replace one at a time

with the ones that are supposed to be there. Photo shows the long

bolts before tightening them up to compress the spring.

Front Brakes: Today I installed the front brake calipers which

had been rebuilt with new stainless steel pistons. Be sure to push

the pistons all the way down into the caliper body because the

brake pads are a tight fit once the caliper is bolted onto the

swivel axle, especially with new brake discs. The brackets for the

brake hose bolt onto the studs. Next I wiggled the brake pads into

place and the little stainless steel shims taking care for the

arrow showing direction of spin for that wheel. The pins and

little cotter pins hold the pads in place. Next, the brake hoses

were screwed onto the brackets. The short pipes from the hose to

the caliper have to be bent to shape and then installed. Now the

whole brake system is in place, but I will wait to add fluid until

later in the assembly. You can also see the coil spring in place.

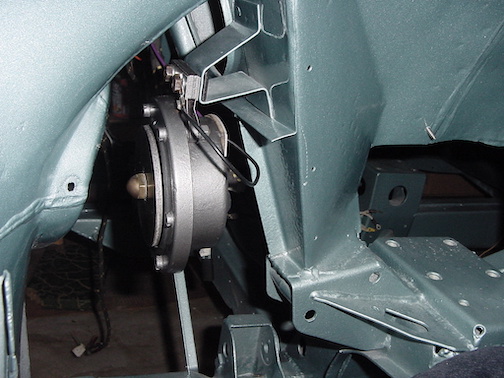

Heater Blower: Today I bolted the heater blower onto the right

inner fender using some fender washers and 1/4 inch screws. The

ground wire had a ring terminal and was secured under one of the

nuts on the inside. I had to rotate the fender washer back and

forth to get it to break through the paint and make a good contact

with the metal fender to get a good ground connection. Haven't

connected the air ducts yet, they seem to get in the way of

accessing the fender screws, but the fenders get in the way of

attaching the ducts, creating a dilemma.

Carpet insulation: This underlayment has a foil side on the bottom

and the fiber side showing. This was cut to size and lightly glued

onto the floorboards, making sure to cut the holes for the seat

attachment bolts and marking the position for the other screw holes

for the carpet snaps.

Rear area carpet: These pieces of carpet had to be trimmed to fit

the rear area around the back seats, and the heelboard. Haven't

glued them on yet, but have cut out the holes for where the seats

screw down.

Aluminum doorway trim panels: Even these panels had to be

modified some to fit correctly. The bend in them was too tight so I

had to unbend them some to fit the contour of the rocker panels.

Then I had to use a file to tweak the ends to get them to fit in the

corners. I clamped them in place to drill the holes for the door

latch, and for the little trim screws that hold them in place. The

rear fenders have to go on first before these can be permanently

attached.

Attaching rear fenders: The rear fenders were the originals that had

been repaired with the patch panels welded in place and smoothed in.

Since the door pillars had been replaced new holes had to be drilled

for the screws to attach there. Before assembly, the sticky anti

corrosion strip was stuck onto the body side and holes poked out for

the screws. The chrome trim strip was taped onto the fender and the

tabs bent over so it stayed in place enough to attach the fender.

The chrome strips had to be bent to fit the curved contour and care

must be taken to avoid kinking them. I had an assistant to hold the

fender in place while I put in enough screws to keep it in place.

Some of the screws were pretty hard to reach but just managed with a

7/16" combination wrench or a socket. As I went around and tightened

the screws, I tweaked the position of the fender and the chrome trim

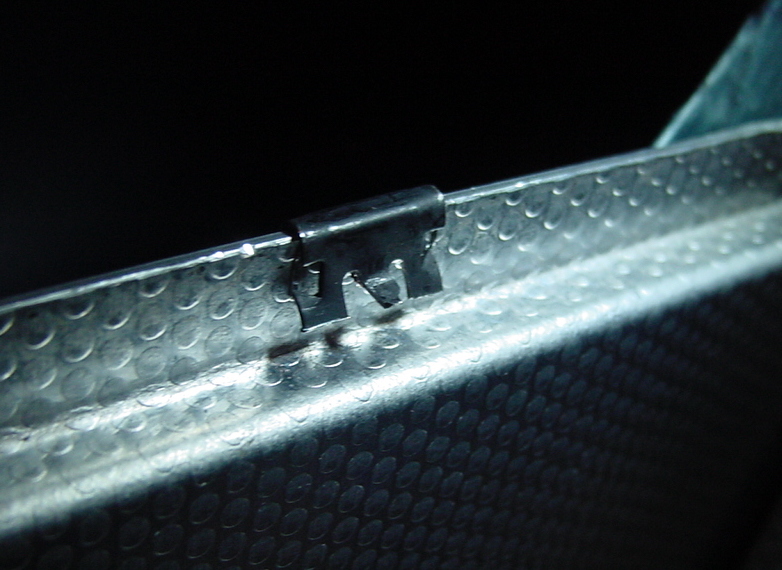

to get them snug and in the right places. The right photo shows

inside the fender where the tabs are bent over to hold the chrome

strip.

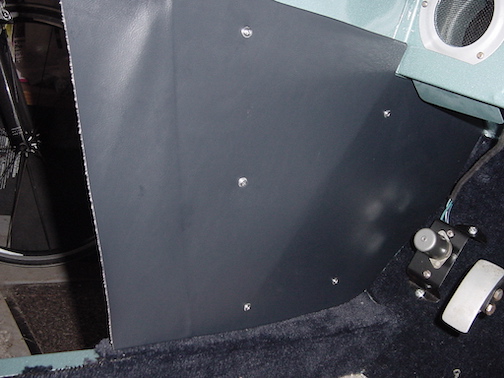

Gas filler and boot area: The boot lid has already been prepared

with the foam rubber weather strip glued in place, hinges attached,

and release handle installed, plus the support rod and the

decorative emblems. The gas tank filler tube goes in through a big

gasket set in place first. A length of rubber hose attaches the

filler neck to the spout on the tank, secured by 2 wire clamps.

Photo shows condition before assembling, and then the finished boot

area. The black panel hiding the filler tank is screwed in place,

and I had to poke a pin through the holes from behind to locate them

so I didn't have to drill new holes.

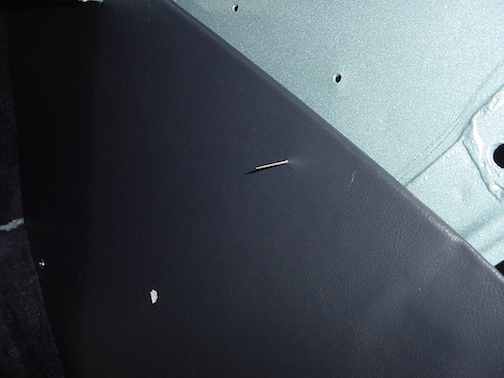

Footwell side panels: These panels are held in place with 5 screws.

I had replacement panels so they didn't have the holes for the

screws. Not wanting to drill extra holes in the metal, I was able to

poke a pin through the holes from the outside through the panel so

locate where to place the screws. The panels fit well and there was

a flap of the vinyl material that was glued to the edge of the

doorway opening.

Heating Ductwork and Front Fenders: Two of the screws for the front

fenders are behind the big air ducts and are hard to reach, but it

is hard to put the ducts in place with the fenders already on, so

the order of assembly is difficult to decide. Here is what I finally

decided.

1. Install the left side fresh air duct. It is just possible to get

a hand around this duct to place the screws on the left fender. Wait

to install the left fender until the engine in in place to allow

easy access to the exhaust manifold and pipes.

2. Put the 2 heater ducts in place on the right side, but don't put

the heater blower in yet. Then I can reach in the space where the

heater blower goes to tighten those 2 screws, and then put in the

heater blower and attach the ducts after the right fender is

installed. Still working on this so will update depending on how

this works out.

If using new ducts, make sure to stretch them out to a little over

the needed size first and then squeeze them in place, much easier

than trying to stretch them once in place.

I ended up putting the heater blower box in place, then put the

fender on, letting the box slip down so I could reach the 2 screws

behind the blower and ductwork, then attaching the air ducts and

then screwing the blower box down in place.

Rear trim Panels: These slip under the slots on the sides, and the

front wood bar is screwed to the door pillar with 4 wood screws.

There are a couple of screws on top of the metal panel, one screws

directly in and the other is in the wood block covered with the trim

material. Sorry for the blurry photo.

Aluminum Door Trim Panels: These go on after the rear fenders are

attached and the rear inside trim panels are attached. They did need

a little trimming at the ends to fit the door opening. Since there

were already holes for the screws in the fender, I held them in

place and marked where the holes should be from inside the fender so

as to not have to drill new holes through all 3 layers of metal. The

welting is held down by the screws, and the core is removed from the

top bit that wraps around the tongue at the top to make it turn the

corner easier. I also cut out some V shaped pieces to help it make

the bends.

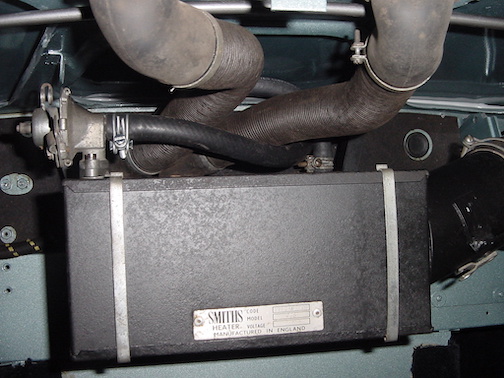

Heater Box: This is screwed on under the dash area. I attached the

hoses first to make that easier. The coolant hoses cross so the hose

from the valve on the heater box goes out on the right side and

leads to the valve tap on the cylinder head.

Padded Dashboard Top: This was new so had to have the holes drilled

for the tonneau fasteners and the screws that hold down the 2 ends.

It was predrilled for the demister and mirror and those holes lined

up pretty well with the holes in the body. I had to cut out the

padding and vinyl for the demister outlets, and then attach the

demister vent covers and the mirror. The wood was fairly straight

and still so I softened it up a bit with some steam on the wood side

and clamped it with a bend and that helped it fit better. The right

hand fender was already on the car so next I attached the rubber

scuttle seal with the copper split rivets. One flap of this fits

under the padded dash top, so I wasn't able to finish the left side

since that fender is not on yet. A little strip of the beaded

welting fits between the dash and the rubber scuttle seal. (The

white spots on the fender are just light reflections, not scratches

thankfully.)

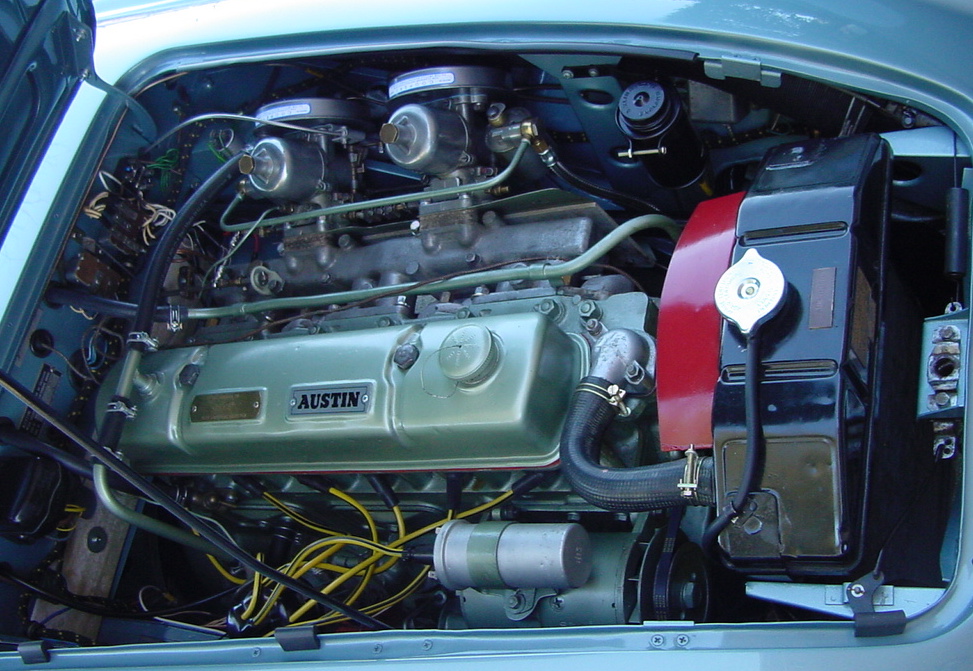

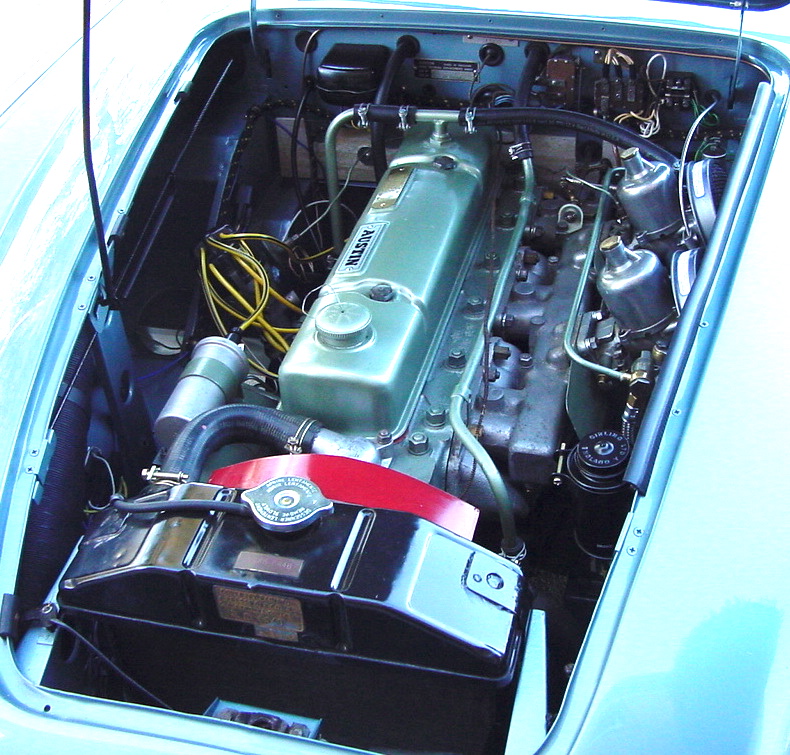

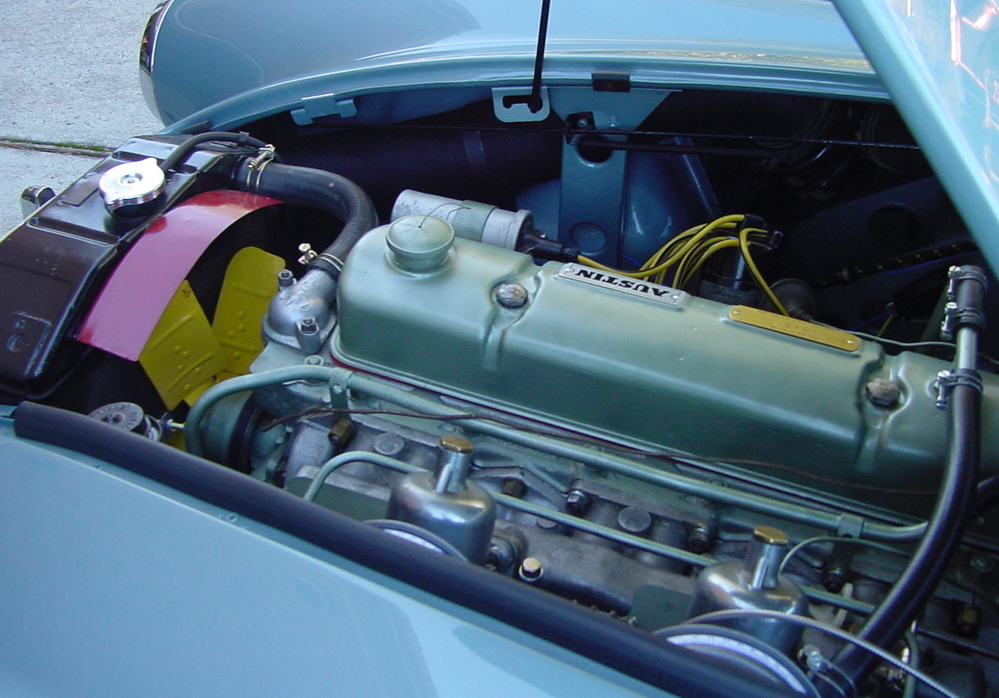

Engine In! Had my son and another friend here today so was able to

get the engine put into the car. My engine lift crane has an

adjustable boom and I had it extended all the way out and still was

unable to reach with the crane in front of the car so we moved to

the side of the car and it was able to reach. I had the engine

suspended so the back end was a few inches lower than the front and

that helped clearing the obstacles. They really made the engine a

tight fit and I had already removed the generator and distributor

for more clearance. Once we lowered is carefully and had it close,

we used a roller jack to lift up the back end of the engine to level

it out and get the front pulley past the cross member. Pay close

attention to the steering column as the motor mount and the heat

shield need to get past it. Also watch the brake pipes on the right

side of the car, the electrics on the firewall, the generator mount,

and the front pulley.

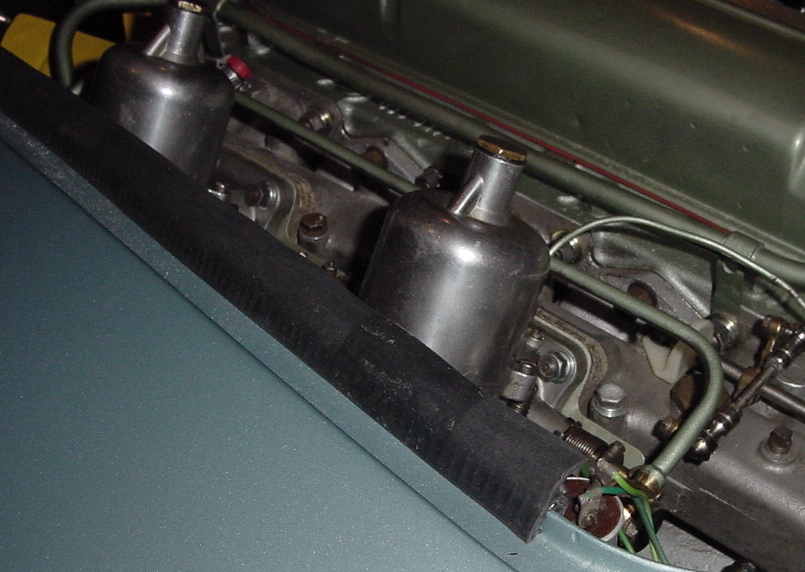

Exhaust Downpipes: These were installed from the side as I had not

yet attached the left fender. They have a copper clad gasket and use

brass nuts. Other items not pictured include attaching the coolant

hoses to the heater, and reinstalling the generator and distributor.

Hood buffers: The long strip buffer just presses on to the left

side, and the 3 small buffers on the right side attach with the

copper split rivets and copper washers. Also in this photo is the

accelerator shaft attached with the white plastic bracket to the top

of the intake manifold with the other end going to the bushing

grommet in the firewall.

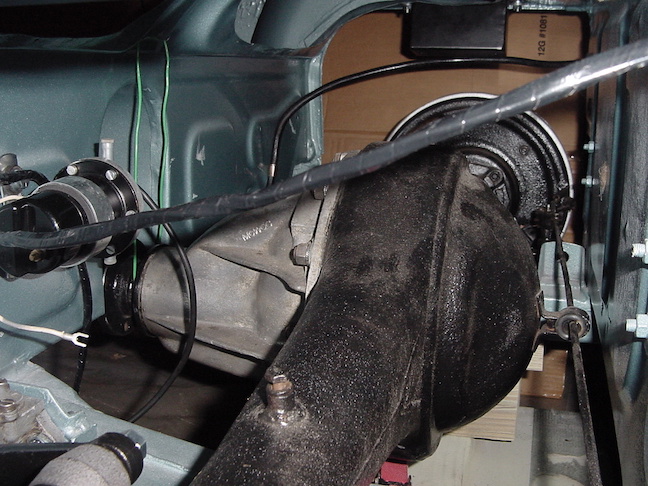

Gearbox (transmission) installed: Had a couple of guys here to help

me put the gearbox in. Seemed harder than it should have been. Start

with the brackets at the rear end removed. The assembly was lifted

into the cockpit at a slight diagonal and back the end into the

tunnel. Use a floor jack to support the weight of the gearbox. I

also used a little bottle jack to slightly lift the back end of the

engine since the motor mounts don't quite hold the back end of the

motor up to the right height. After backing the overdrive end into

the tunnel there was room to swing the bell housing roughly into

place. (We had a piece of plywood covering the opening in the floor

of the car until the bell housing was in position, then we raised

the floor jack and slid out the plywood and supported the gearbox

with the jack.) It took several hands to keep the unit balanced on

the jack and then carefully lower it into alignment with the

flywheel. We had to rotate the shaft a little to line up the splines

and then wiggle it forward and get some bolts in place. Once

everything was in place the bolts were tightened down. Then the rear

mounting brackets were bolted onto the back end of the overdrive and

onto the chassis, and the engine motor mounts were also given a

final tightening. There is a tie rod and bushings that attach the

loop underneath the overdrive to the frame.

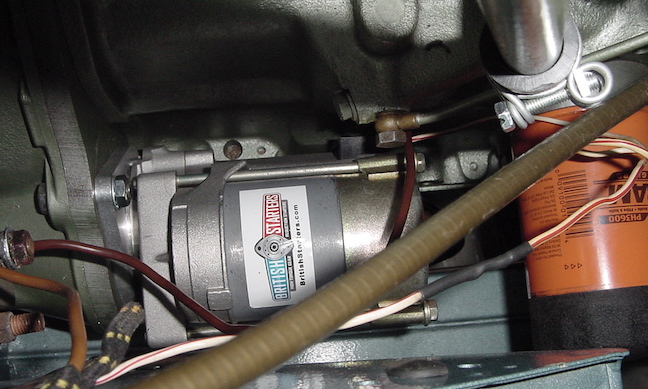

Starter Motor: One of the concessions to modern technology that I

allowed was to get the new gear reduction starter. It has a mounting

plate on the front with set screws that allow it to mount in

different rotational positions, but none of the options allowed it

to fit so I had to drill 2 new holes in the plate to make it fit,

and even then it was a tight squeeze. The other thing in the photo

was an oil filter adapter that allows you to use a regular spin on

oil filter instead of the original canister type.

Close up of Oil Filter adapter: Spin on oil filter adapter from Moss

motors, makes it easy to change the filter, and less prone to leak

than the original oil filter. Just bolts on to the original tapped

holes so no permanent modification and original filter saved for

posterity. The upper left edge of the adapter contacted the casting

on the engine block, so I actually had to file a tiny bit off the

edge of the adapter at that spot. I tried putting it on 180 degrees

so it looked like it should fit better, but the oil holes didn't

line up properly so this was the orientation that was necessary for

it to work right.

Clutch slave cylinder: This just bolts onto the bell housing and

connects to the clutch hydraulic line. There is supposed to be a

rubber boot over the lever so I will have to add that later. You can

also see the grounding strap that connects the bell housing to the

frame for electrical conductivity.

Bonnet On it: Had some helpers to help put the bonnet (AKA hood in

the US) on. The hinge levers attach to the pockets with some clevis

pins inserted from under the dash. Then you have to make sure to

have one flat washer and one wavy washer on each side of the pin

before you put the cotter pin through the hole. This requires

squeezing the flat washers in order to flatten the wavy washers to

be able to insert the pin. I ended up grinding one of the flat

washers thinner in order to be able to get the cotter pin through.

The hinge bolts onto the brackets on the bonnet, and then you have

to adjust the position of the hinge within the slots on the bracket

to get the bonnet into the right position up-down and front-back. I

also had to adjust the spring release at the front of the bonnet to

get it to catch and release smoothly.

Instrument Panel: I hung the preassembled panel on some bungee

cords so I could wire up the instruments before bolting it on so I

didn't have to spend so much time on my back looking up under the

dash. I had one short when I applied power. One of the wires to the

headlight switch was in contact with the bracket on the fuel gauge

that holds little light bulb and created a dead short. I rearranged

the positions of those items to fix the short and everything seemed

fine, but the bulb in the fuel gauge was blinking on and off. I got

up under there and replaced that bulb, and turns out that bulb was a

blinking bulb, with the little blinker strip inside the glass! I

don't know where that came from but replaced it with a correct one

and works fine now. The instrument panel bolts on with 4 screws.

Oil pressure and Temperature gauge: This was installed after the

dashboard was in place. The thermometer sensor screws into the

cylinder head near the front of the car and is permanently attached

to the gauge, with the grommet that fits in the firewall. Once you

get the sensor threaded through the hole in the instrument panel and

over the heater, through the firewall you can get it into position

to screw it in. I think it made about 4 revolutions once it was

threaded and I had put one reverse loop into the capillary tube and

then as it turned you have to make about 3 more loops up near the

firewall to take up the twist and slack in the tube.

Steering Wheel: Most Healeys had the adjustable steering wheel that

slides onto the column, with a little pushing, make sure to put on

the chrome springy coil and collar first. I had already put in the

long tube down the column so had to thread the wires down through

that. I slid a stiff insulated 14 GA solid copper wire up the tube

from the front and then taped the wires onto that and pulled the

wires out the front. I had to cut off the little bullet connectors

first so soldered new ones on after it was in place. It is a pretty

snug fit getting the wires down through the tube.

Front seat bases: The sliding rails sit on top of the wood

spacer strips and are bolted on with the T nuts from underneath. I

had the original floor pans so didn't need to drill any holes. The

base frames then bolt on to the sliding rails. The outside stud for

the seat back was very close to the side panel so it will be

impossible to unscrew the acorn nuts without loosening the seat base

frame off the sliding rails, then attach the seat back and acorn

nut, then bolting the base frame back onto the sliding rails. That

seems to work. You can also see where I installed the seat belt

anchors through the floor pan.

Front Grille: The front grill can be wiggled in from the front with

the radiator air deflectors detached at their bottom connections.

The three tabs at the top are held in by bolts from behind the

shroud, through the grille tabs and into the threaded holes in the

chrome top cowl. The two outer lower tabs bolt to the shroud and

also hold the radiator air deflector and the braces for the splash

guards.

Now the top cowl is installed.

Windscreen washers: The jets attach through the shroud and best I

can tell they point outward with the tiny hole aimed at the

windscreen. The tubing then connects to the pump and reservoir.

Front Bumper: The bumper bar is a new one, and after trying on the

brackets, they turned out to be so bent out of shape I had to buy

new brackets, or spring bars, too. I also got a new splash

apron and that has been painted body color by the paint shop. The

slots in the splash apron didn't line up with bolt sockets in the

bumper so I had to modify two of the slots with a grinder to get

them to fit. I also had to slightly modify the bolt holes in the

bracket where they bolt onto the frame to get the brackets to clear

the bottom of the front shroud. When that was done, I loosely bolted

the brackets onto the frame, then placed the apron on top of the

brackets with the front edge of the apron over the front of the

brackets. Then the bolts go through the holes in the brackets, the

slots in the apron and into the bumper. A bit tricky to push and

shove the bars in place to get everything to line up, but finally

got everything together and tightened up all the bolts. The gap from

the apron to the shroud seems a bit wide, but will live with it.

Fuzzy door seals: Variously called Furflex or Bristleflex, this

strip runs all the way along the door opening. I think originally it

was just pressed onto the rim of the opening but now they sell

little clips to help it stay in place. Even with those clips, it

still didn't seem to catch hold of the aluminum strip and I ended up

modifying the clips, making the legs shorter and creating a little

tab to stick out and catch the trim piece. Even with the modified

clips, it was difficult to get the strip to press in to the corners

and stay put, but seems to finally looking OK now. I started at the

rear and worked my away down and forward and then the little

aluminum cap holds down the back end where it was started.

Windscreen on: Today I put the windscreen on the car, aka

windshield. Should have been easy, but was difficult to push the

windscreen assembly down far enough to get the holes in the body to

line up with holes in the windscreen posts. Since the body

shop had the shrouds off I think they were replaced a hair too high.

Anyway, I managed to get it bolted back on and will put on the

wipers after I make sure they are in their "parked" position.

Really starting to look like a car now.

Car is mostly put together now. Need to add coolant, or water

to start with, to the radiator and check for leaks, then get the

ignition timing in the ballpark enough to at least get the engine

started. Then I will purge out the fuel lines to get rid of any

debris and then hook the fuel lines back up and check for fuel

leaks.

Other items still on the to do list include: Set the toe-in on the

front suspension, install transmission tunnel and carpet, assemble

convertible top, and tune up engine once it is running.

Tonneau Cover: I had ordered the blue tonneau cover and convertible

top cover several years ago. The tonneau came with the Tenax

fasteners already installed and they fit correctly. It was a slight

stretch to get the dashboard snaps to fit, but was able to get them

to fit. I bought new tonneau stiffener bars and I thought that they

were too long, but I found on the Moss Motors webpage a description

of how the stiffener bars were supposed to fit. See photos below, as

the bars extend over the sewn seam and the flap folds down over the

end of the bar in what looks like an unusual configuration, but the

turnbuckles fit right like they are supposed to and the extra fold

in the flap reinforces the top layer of the tonneau to help prevent

the end of the bar from poking through. So don't cut off the ends of

the bars to help make them fit.

Dec 24, 2020: Got the engine running over the past few days. A

little trouble initially getting the timing and carb settings in the

ballpark to start it up, but managed. I noticed that the tachometer

is not working so may need to get a new cable for that, hopefully

not the tachometer itself, but I had tested it with a drill and

seemed to work prior to installation.

Convertible top: The top needs to be assembled and the Tenax snaps

need to be installed. I put on the frame support and attached to

aluminum rail to the underside of the wood bow and attached the

clamps. then draping the top over the frame put the top in position

and started installing the Tenax snaps. Punch a 5/16" hole in the

right spot and spin on the snap and tighten with the little tool.

Still in progress at this point and might wait until spring and work

on it when it warms up. they say if you stretch it outside on a warm

sunny day, the material stretches better and you get a more snug

fit, so just doing the snaps for now.

Working out some kinks: Got the engine started but no test drive

yet, trying to get the engine tuned up some. Timing is set pretty

well now and I think the carbs are set somewhere in the ballpark to

sound decent, but tuning them is sort of by ear. Will note some

problems and actions taken below.

Tachometer needle bouncing up and down. I

can hear intermittent clicking noise in the tachometer as well.

Action taken: Installed new tachometer cable and works normally now

with stable reading and no noise.

Choke control nearly impossible to pull out: This

was the original control cable and was pretty badly kinked up in a

few places, also looks like it had been cut and was a hair short so

barely able to secure it in place. Bought a new cable that comes

with the knob already attached. These are supplied with about a foot

of extra length, so had to be trimmed down to size, carefully so as

to not make it too short again. Installed, trimmed, tightened up the

secure points and operates smoothly now.

Clutch won't disengage: This was a tough

problem and still not sure I am done with it. Car has new clutch

plate, release bearing, and all new clutch hydraulics

including master and slave cylinders and all pipes and hoses. System

was bled and rebled. Pedal stops about an inch from the floor so not

getting full excursion of the slave cylinder. From resting position,

I noted that I could push the push rod back into the slave cylinder

about a full inch so it was starting its action about half way

through its full travel. When I bought the car as a barn find

project, it came with a gearbox that has a BN-4 tag on it, so

obviously the original gearbox was swapped out at some point with

and older one. The older one had a slightly different bell housing

and used a 9.5 inch diameter clutch. My engine is original to the

car and used a 10 inch diameter clutch. That bell housing is not

compatible with my engine, as the pressure plate didn't fit inside

the bell housing in particular on the casting by the clutch fork.

Turns out previous owner had shaved off enough metal to get the

pressure plate to clear the bell housing, just barely. Must have

also been a slight difference in the distance from the clutch fork

to the pressure plate release bearing surface with this mismatched

set up compared to the original. Anyway, I ended up fabricating a

new slave cylinder push rod about 3/4 inch longer than the stock one

and clutch releases normally now. Still waiting for a road test, so

the final word is not in yet on this issue.

So here is a

photo of the fabricated pushrod and the donor Torx tool set.

So here is a

photo of the fabricated pushrod and the donor Torx tool set.

Waiting to install the tunnel cover until after a

road test in case I need to do any more work there.

Got the slave cylinder push rod installed and tested OK, shifted

very smoothly and snychro worked well in 2, 3 and 4th gears. First

test, the rod was a bit too long and the clutch released quite high

and something scraped when the pedal was all the way down, so

shortened it up about 1/4 inch and that seems to be about right.

Finally getting it out of the garage so here are some photos of the

nearly finished car.

Finally got the convertible top installed,

Back to

Scott's Crystal Radios